Indirect cooling technology takes the ‘heat’ off producers

By Igor Makarenko

Innovative potash cooling practices are giving producers the tools they need to remain competitive amid low commodity prices.

A steady decline in potash prices from highs of near $500 US per tonne in 2011 to sub-$200 today means plant operators are on the hunt for improved efficiencies within their existing processes. In part, this has highlighted historic challenges with existing direct cooling solutions that typically come with high operating costs and are less flexible in adapting to varying processing conditions.

Vertical plate technology that cools potash indirectly has emerged as a Goldilocks solution that puts temperature control back into operators’ hands while also reducing energy costs and improving storage management practices.

Potash must be cooled to a specific temperature range before it can be safely packaged and transported. In most cases, the potash will come into the cooling stage at a temperature of 100°C or higher and should exit the cooling stage with a target output in range of 50° to 60°C to be safely handled and avoid caking.

Yet when throughputs exceed existing processing conditions, direct cooling solutions such as fluid beds and rotary drums cannot cool the product to temperatures needed to meet these conditions. As a result, the potash must be moved to large on-site storage facilities where it is left to “stack-cool” anywhere from three to four days. When that product finally cools, it is then conveyed to loadout where it is packed into trucks or railcars.

The challenge with stack-cooling bulk storage is it complicates plant logistics – for example, demurrage and warehouse management – not to mention increases the likelihood of caking and forces the product to sit rather than being sold. In addition, potash is a great insulator, meaning even after sitting for extended periods of time, it can still be dangerously hot in spots and therefore potentially hazardous to operators and truck drivers at loadouts.

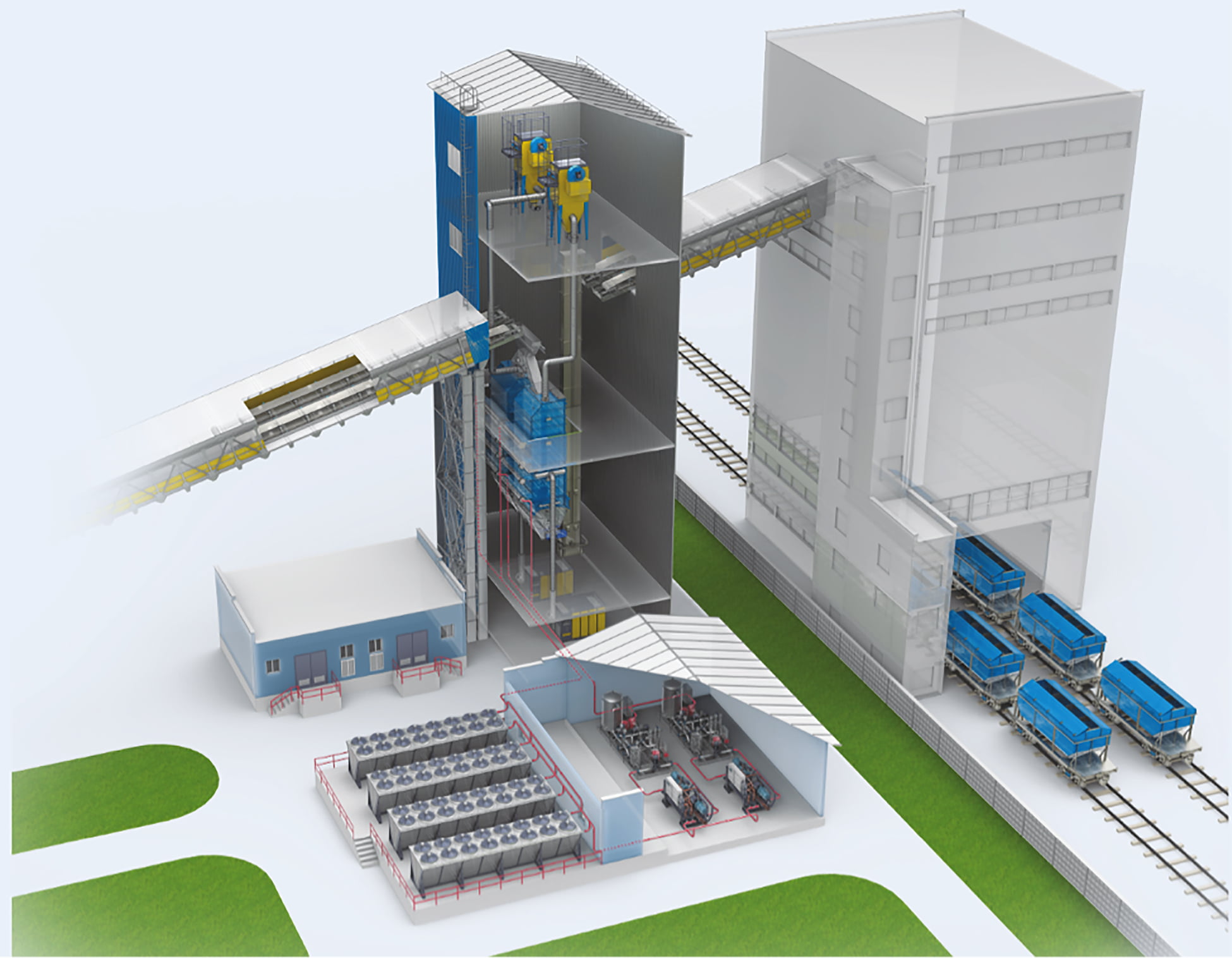

Vertical plate technology is flexible and robust enough that it can accept more product while still meeting cooling requirements. A tall, tower design allows the product to slowly pass through stainless-steel heat exchanger plates that are cooled by water or other liquid mediums. The plates absorb the heat and the product cools as – encouraged by gravity – it slowly and uniformly moves downward, controlled by a discharge device.

The design allows true counter-current flow of the water inside the plates, which achieves greater thermal efficiency, and as a result, more effective cooling. In addition, the plate design offers more surface area to cool the product than beds or drums, and in a more compact space. The typical required footprint for a vertical heat exchanger is two metres by two metres.

Combined, these factors allow plant operators to not only handle higher throughputs while still guaranteeing a safe and even-temperature product that won’t subsequently cake during further transport, but it also gives them a conveniently located cooling stage directly at loadout. That, in turn, frees up space within the main facilities, mitigates the need for housing product in flat storage, and puts the safest possible product to handle into truck drivers’ hands.

Because the potash is cooled by conduction as opposed to convection (air cooling), indirect cooling technology also foregoes the need for high-energy consumption air chillers and large fans. Rotary drums and fluid beds come with large-scale fans for pushing and pulling air and wet scrubbers or baghouses to clean the air to meet emissions requirements.

These pieces of equipment come with high energy costs and require significant space. In a typical 3,600 tpd potash plant, the operating power requirements of a typical fluid bed is 1,040 kW – compared with just 100 kW with indirect cooling technology.

To learn more about indirectly cooling potash, visit solexthermal.com.

Igor Makarenko is global director, fertilizer at Solex Thermal Science, a Calgary-headquartered company specializing in bulk solids thermal exchange.