With over 100 screens in Russia, 75 in Canada, 36 in Israel, 20 in Chile and 6 in Jordan, Derrick Corporation helps potash producers meet product grades and specifications by increasing overall plant efficiency and product recovery. These contributions span many decades of successful service to the potash industry around the globe.

Derrick works together with global potash producers to improve mill recovery and efficiency. Its proprietary high capacity, high efficiency product design has proven to be a robust, reliable screening solution, ensuring that operations capture as much product as possible with minimal additional work. Derrick’s unique urethane screen panels reduce near-size blinding to maintain optimum efficiency, while offering unmatchable panel life.

In addition, the Derrick Stack Sizer replaces conventional high amplitude horizontal screens, which commonly utilize a sieve bend prior to the screening surface. Conventional screens offer low screening efficiency, higher circulating loads, high structural maintenance costs due to dynamic loads, and excessive brine spray on the screen deck to liberate fines.

Applications

- Primary ore sizing screens – 3.2mm to 4.5mm

- Regrind screens – 1.4mm, flotation tails are screened

- Fines column concentrate screens – 0.6mm to 0.7mm

- De-sliming screens – slime removal at 1mm

Benefits

Efficiency

- High-open-area urethane screen panels prevent blinding and will last 20 to 30 times longer than the average woven wire panel.

- Proprietary 70 mesh urethane panels—primary wet screening from crusher to flotation—have approximately 35 percent open area, compared to 10 percent for competitor urethane panels.

- Repulp troughs and spray bars reintroduce brine to free up fines trapped in the product bed. In conjunction with Derrick’s high frequency low amplitude vibratory motion, the repulp process produces cleaner oversize product, reducing the load on the flotation cells and saving costs for additional reagents such as amines.

Maintenance

- Very low maintenance requirements

- Easy and fast panel replacement

- Sacrificial, replaceable anodes help prevent corrosion on the live frames in the harsh potash environment

- Motors are self-lubricated and have exceptionally long life

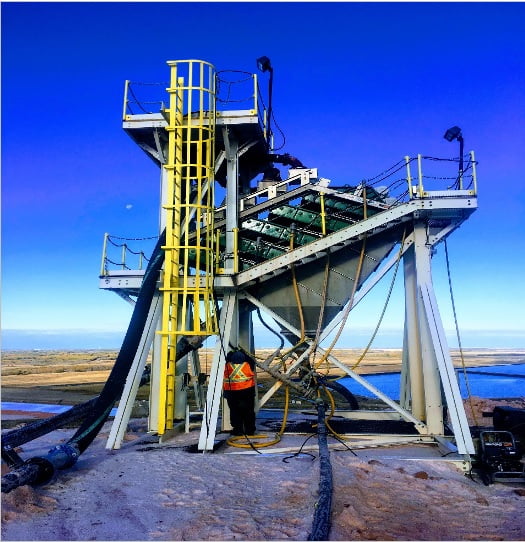

Case Study – Derrick Stack Sizer Increases Capacity and Recovers Product From Potash Tailings

Background

A company headquartered in Saskatoon, Saskatchewan, Canada produces and supplies bulk salts and packaged ice melters for business, municipal, and retail use in North America. The company offers salt crystals for highway de-icing, feed, hide curing, and drilling mud, as well as salts for water softening and road stabilization. Over several years, the company had experimented with various flowsheet options to improve classification efficiency and increase production rates.

The plant receives potash tailings containing a high level of NaCl from major potash producers in Saskatchewan. The company concluded that through additional sizing and removal of fines from the tailings, an environmentally friendly option could be produced for several applications.

Solution

Full-scale laboratory tests were conducted in Buffalo, New York, U.S.A. to determine the efficacy of the process. Test results indicated that the Stack Sizer could eliminate more than 90 percent of fines. The unit was equipped with1.2mm Derrick non-blinding, exceptionally high-open-area Derrick Polyweb® polyurethane screen panels. Following successful full-scale test results, the customer decided to purchase the Stack Sizer.

After completing the Stack Sizer installation, the following results were obtained:

- Production rate rose by 35 percent.

- Overall plant availability increased due to long-lasting polyurethane screen panels.

- By drying only the final product, rather than entire feed, energy consumption was significantly reduced.

- Initial calculations indicate that ROI was 166 percent, with payback in just 4 months.